The whole mushroom is more than just an extract

We have been convinced since the very outset that there is no more appropriate formula of the health promoting mushrooms and plants we can offer to people than that offered to us by the Nature itself. We do not want to deprive people of any of Nature’s perfect creations but rather wish to be a bridge between Nature and our customers. Each mushroom or plant contains a unique range of health promoting substances. This is not just an empty phrase but something that has been proved by countless studies on every single species of medicinal mushrooms. The Traditional Chinese Medicine has a long-standing knowledge of this fact, time-tested during thousands of years, long before the emergence of any modern methods of identifying the presence of single substances in and their effects on human body.

Thus, you will always find a complete mushroom in our nutritional supplements with all the substances preserved in an optimal ratio for the human body. Extraction is the opposite method. What happens during an extraction? The process of extraction results in the obtaining of only one single substance (e.g. a beta-glucan) while all the others get lost uselessly. So, for example, our 100% dried Oyster Mushroom contains not only beta-glucans but also lovastatin, mushroom fibre, vitamins B, D, C, and K, trace elements (copper, chromium, zinc, selenium and iodine) with their interactive effects. We would deprive our customers of those valuable substances if we implemented an extraction process.

"Extracts derived from mushrooms are just a soloist, while a mushroom used as one whole is a quite well coordinated symphony orchestra."

S. T. Chang, a biology professor, Vice President of the World Society for Mushroom Biology and Mushroom Science, member of the Executive Committee of the International Society for Mushroom Science.

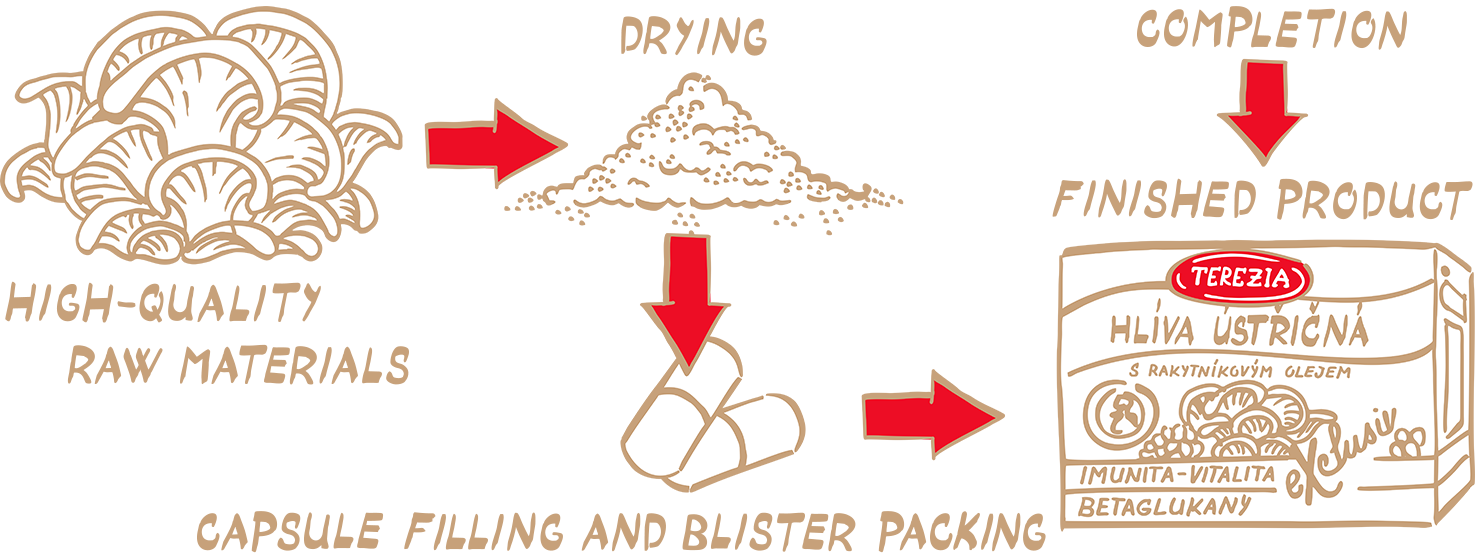

Lyophilisation – a guarantee of preserving all active substances

A mushroom must pass through a drying process before it can be powdered and enclosed in capsules. Our society has decided to apply the so-called lyophilisation (freeze-drying) which is a manufacturing process during which water is not removed by evaporation but by sublimation of ice from the food, [i.e. through s direct conversion of ice (water in solid state) into gaseous phase without melting]. Through an appropriate primary freezing the food is turned into solid state keeping its original structure, colour, flavour and scent and, primarily, all the active substances contained in the dried mushroom fruit-bodies. Thanks to lyophilisation a pure natural product free of admixtures and dyes can be achieved.

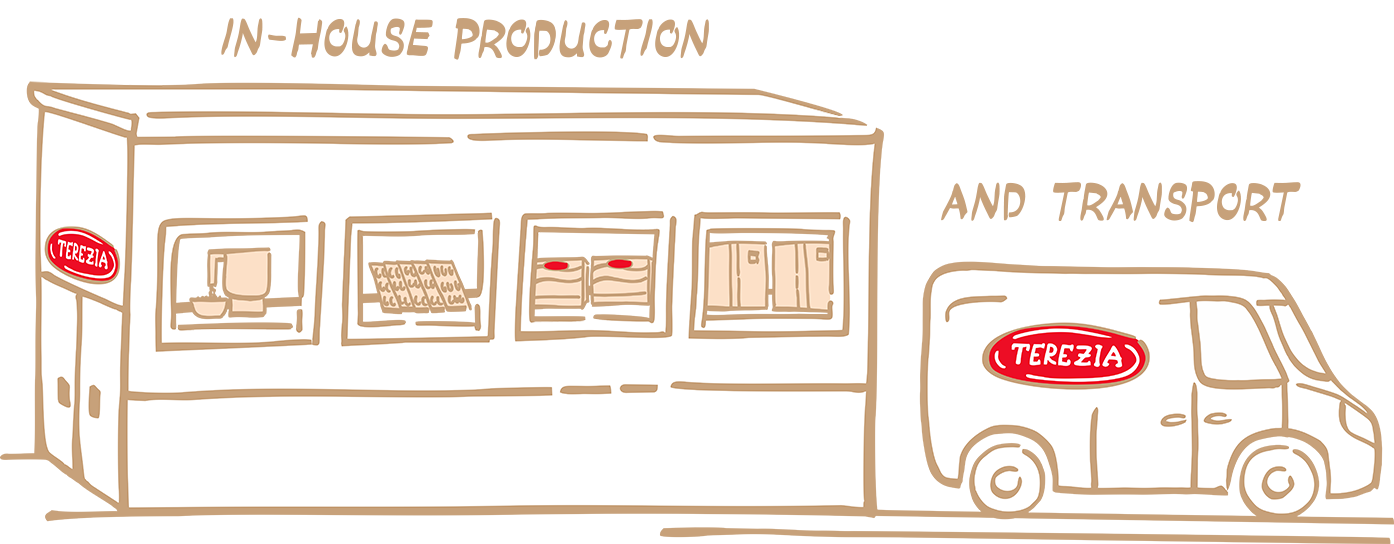

Our own certified production facility

In order to be 100% sure that the verified raw materials we use will not lose any of its value during the production process and that we will really be able to oversee the entire process of manufacturing of our food supplements we have decided to have our own production facility, one that is now situated in the town of Brandýs nad Labem. It is a HACCP (Hazard Analysis and Critical Control Point) certified production process, a system a qualified implementation of which leads to minimising and, possibly, to excluding potential illnesses or health impairments of food consumers. The HACCP system is based on the knowledge of the critical points, i.e. areas with a highest possibility or probability of microbiological, chemical or physical contamination of the food chain. Those points are the most significant checking positions and are monitored, evaluated and controlled in a manner to prevent any contamination (this includes, e.g., the units of freezing, raw material handling, intersections between clean and unclean operating areas etc.). The production process includes the mixing of ingredients, machine-operated and manual capsule filling, blister packing as well as finished product packaging for the end customer.

Doing the job without chemicals

The chemical compounds contained in countless medicaments and food supplements have been proven to be harmful to human body. However, we want to help people rather than to cause damage to them. This is why we do not use any production process accelerating preservatives or add dyes and chemical fillers to food. We clearly prefer purity and quality.